Introduction

This is my experience replacing a car battery for the first time on our 10-year old family wagon.

Symptoms

The car is an automatic. It starts when the brake pedal is depressed and the start button on the dashboard is pushed.

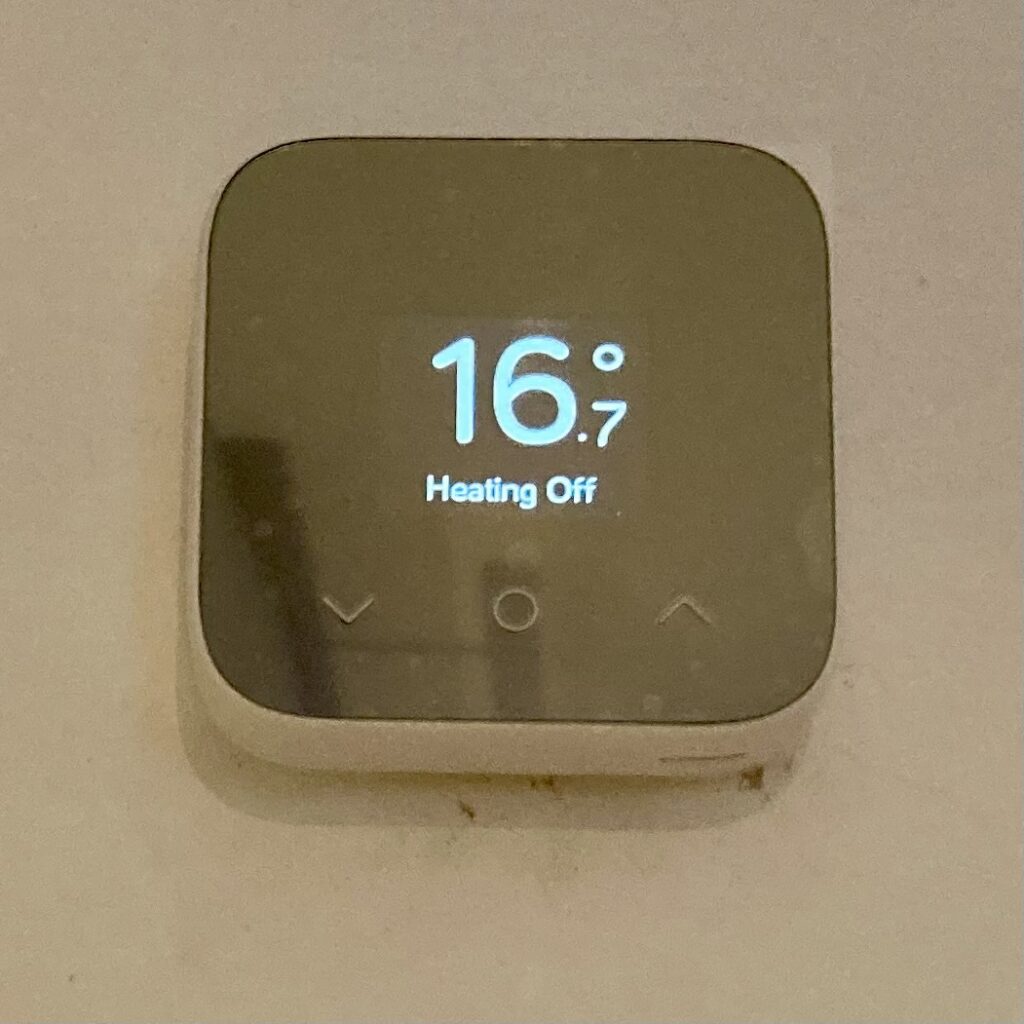

Despite a number of long journeys, the start button began taking longer to start the engine. A wait of 5 seconds or more became normal. I decided to ‘pop the hood’ and measure the battery voltage using my multimeter. The overnight reading, when the battery was ‘cold’, showed 11.7 volts. When the engine was running, the reading was 14.3 volts. In summary:

- 14.3V – the alternator was doing its job, but,

- 11.7V – either the battery needs re-charging or replacing.

Given the age of the battery, it seemed pragmatic to replace it before attempting any further investigation.

Specification

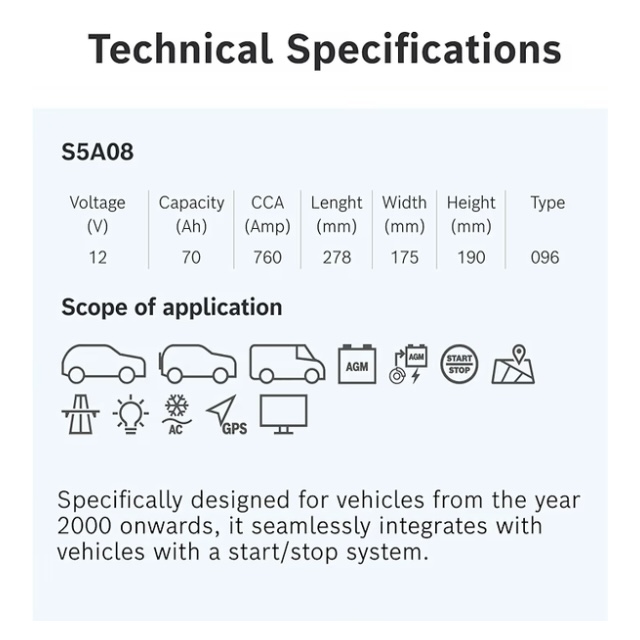

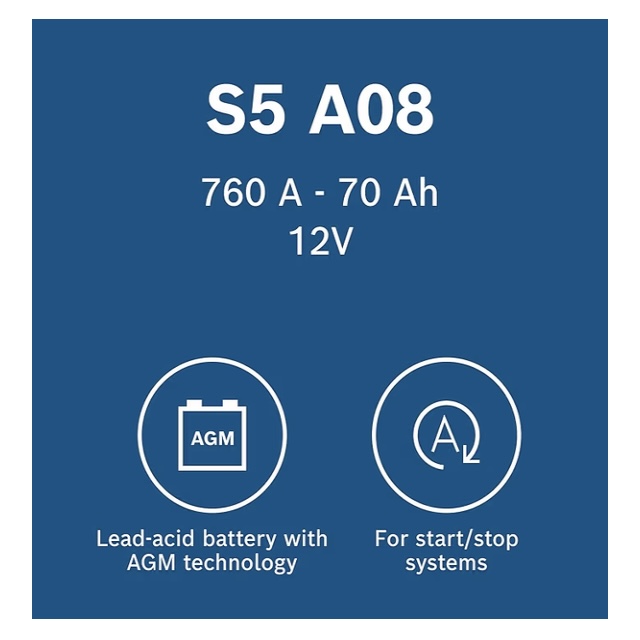

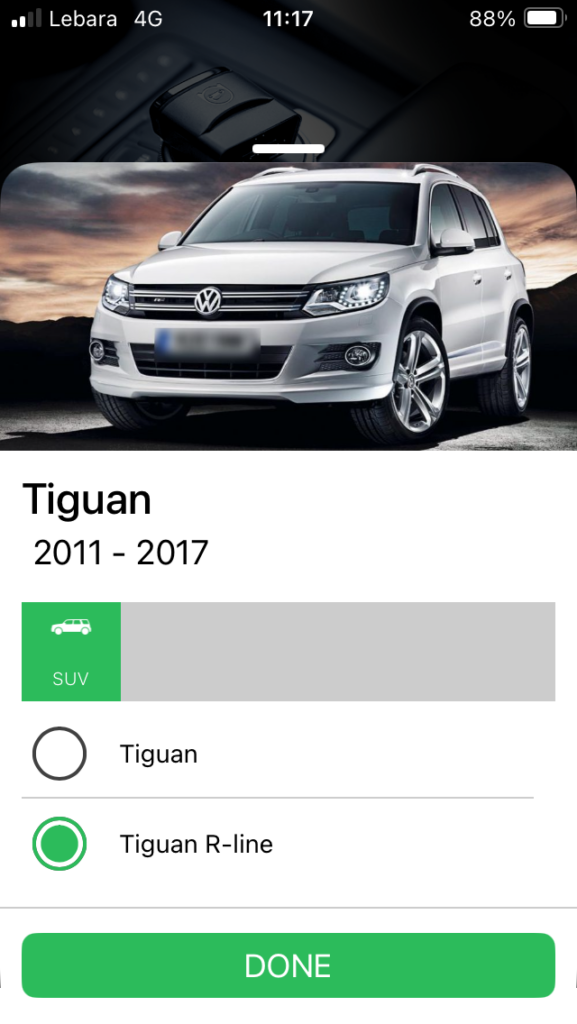

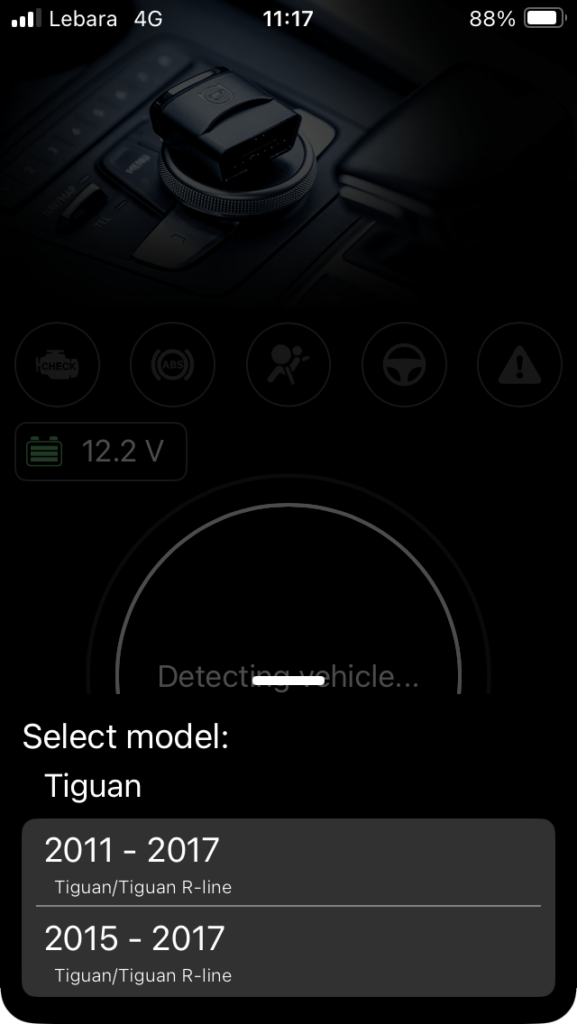

We have a VW Tiguan 2.0 TDI R-Line 4-Motion (5N) first registered in March 2016. It was supplied with a VARTA 12V AGM battery offering 68Ah capacity and start/stop capability. When entering the car registration plate into various websites I was presented with three options.

The Price Is Right?

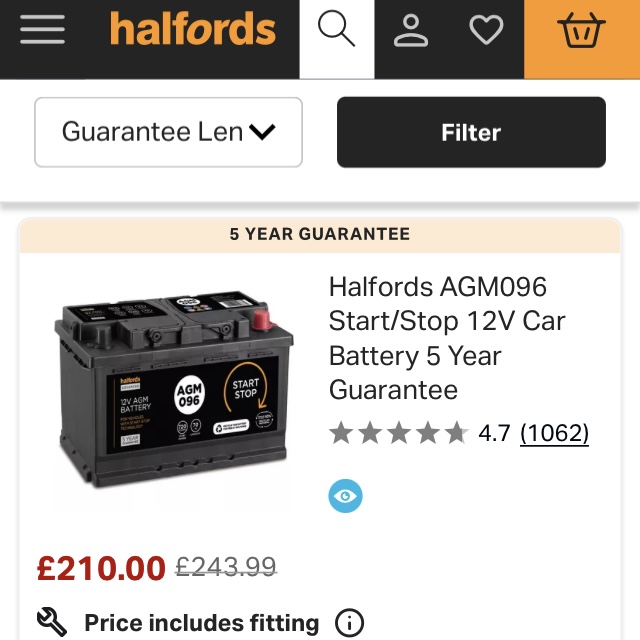

- Halfords, £210 for supply and fitting (plus disposal of the old battery) for an own-brand battery with a 5-year warranty

- Kwik Fit, £267 for supply and fitting (plus disposal) of a Bosch battery, 70Ah capacity with a 5-year warranty

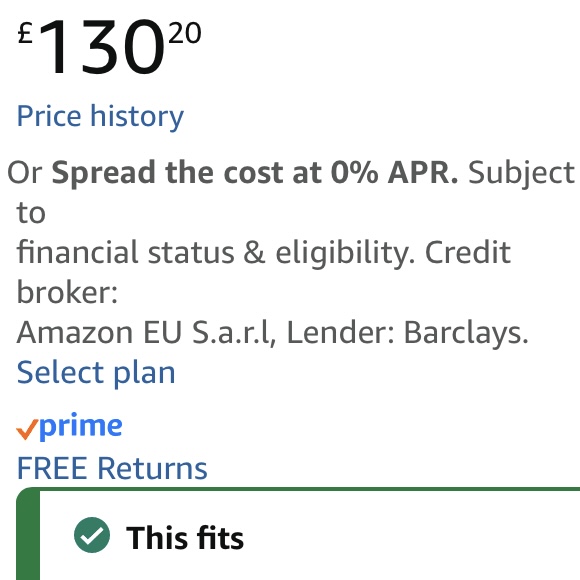

- Amazon, £130 for home delivery via Prime of the same Bosch battery above.

The decision was straightforward: how hard could it be to fit a car battery?* I would save a considerable amount, learn a bit about car maintenance thereby avoiding a trip to the garage.

*Spoiler alert, not quite the saving I first thought.

Research

The Bosch battery arrived within 24hrs from Amazon. Meanwhile, driving the car felt like playing Russian roulette. Would the current battery be strong enough to restart the engine and get us back home? So, the pressure was on to get the new battery installed as soon as possible.

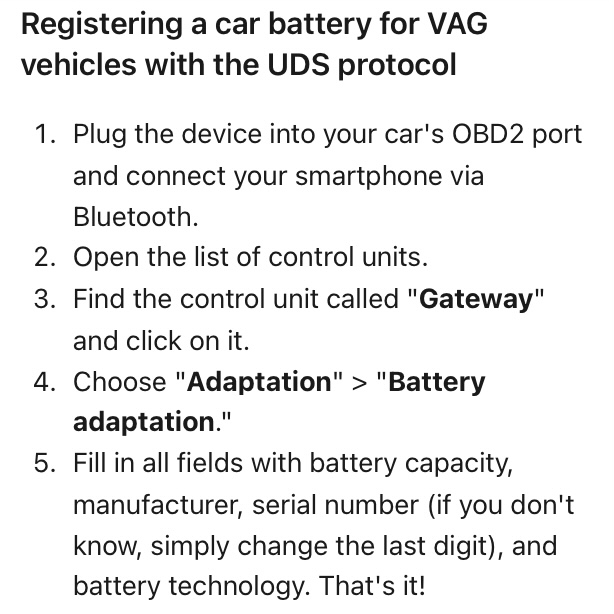

The online investigation began in earnest. Advice was consistent: always disconnect the negative battery terminal first, and the positive last. Re-connect in the reverse order: positive first and finish with the negative. Then, another forum talked about coding the battery, and after a bit more research for our vehicle, the reality dawned that coding was a mandatory step. Hmm.

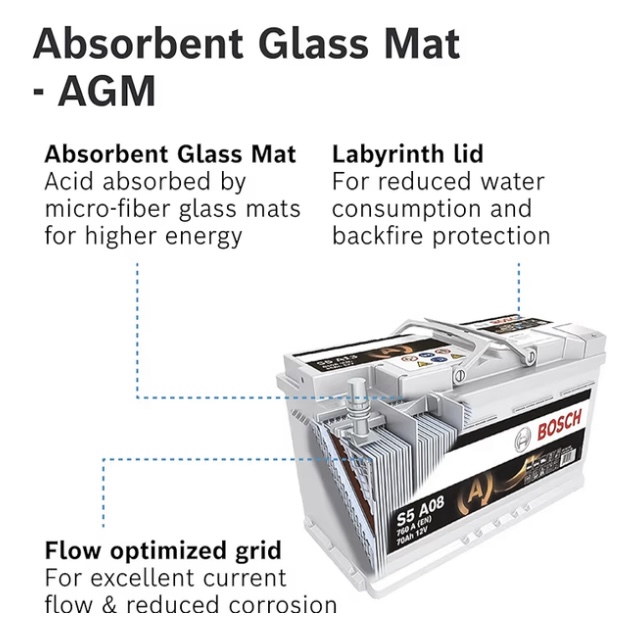

Battery Coding

Coding the car battery ensures the charge profile, managed by the car, is appropriate for the capacity, chemistry and age of the car battery. This avoids premature aging of the new battery.

Bosch!

I called our local independent tyres/ batteries/ MOT outfit to look at my options. The response was: ‘No, we wouldn’t code a battery we haven’t supplied and fitted ourselves’. It was unlikely Halfords or Kwik Fit would respond any differently. Hmm again.

OBD2

The £130 was a sunk cost. Sending the battery back to Amazon for a refund was not an option. I started to investigate OBD2 readers. OBD2, or On-Board Diagnostics II, is a standardised system in vehicles that monitors and reports on the performance of the engine and other essential components, primarily for emissions control. It allows mechanics to access diagnostic trouble codes (DTCs) and real-time data to troubleshoot issues effectively.

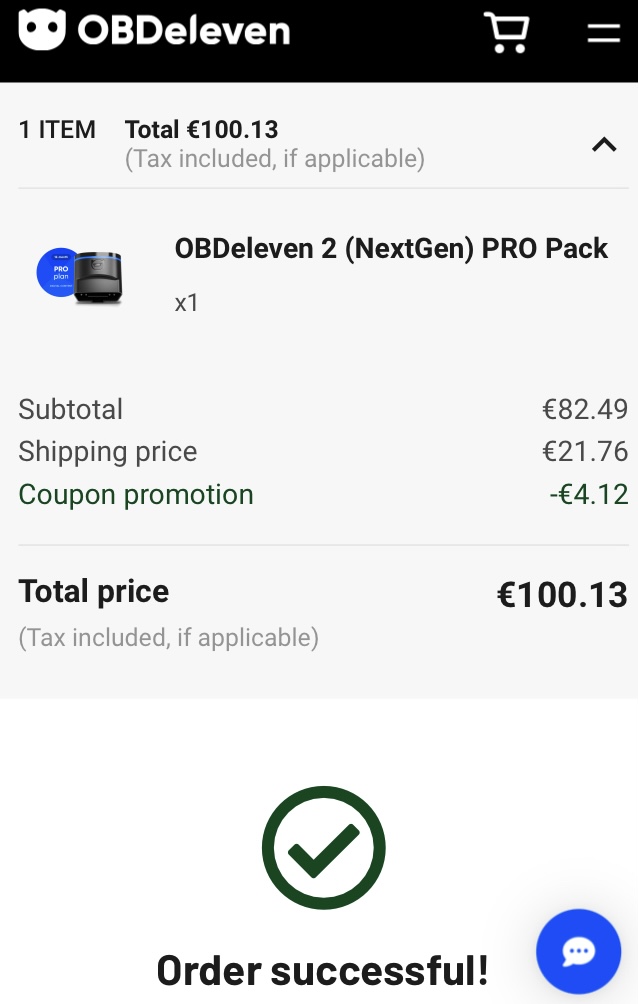

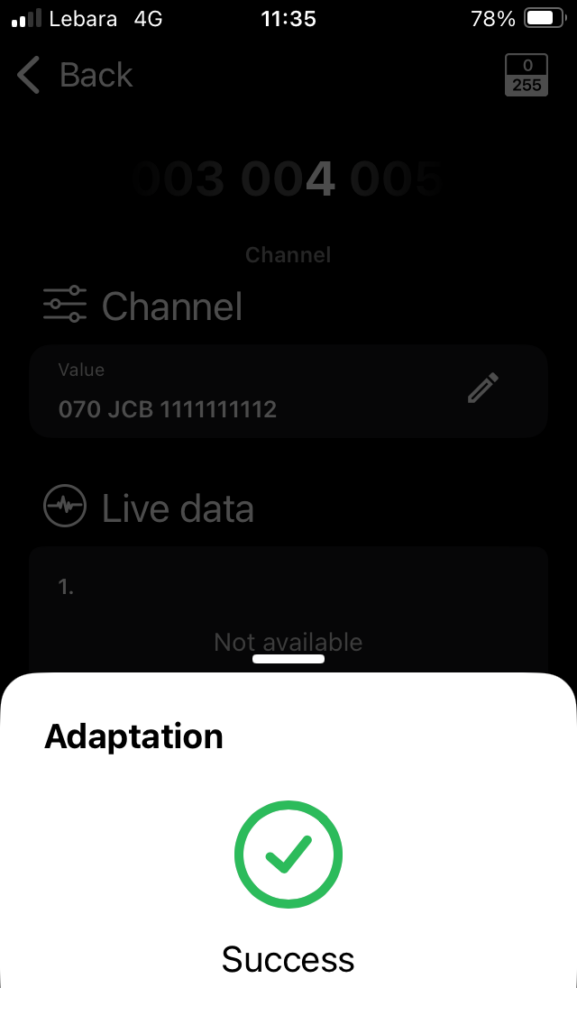

OBDeleven

Various forums recommended the OBDeleven brand of OBD2 readers for VAG cars. I ordered a ‘NextGen’ device from them directly. However, there is a catch, OBD2 readers are simply that – they read data only. I needed an OBD2 reader that can also write data back to the car’s computer. This requires a PRO subscription for a minimum one year period. Reluctantly, I order the OBDeleven reader plus the subscription for £88 (€100 with fast delivery).

ChatGPT explained that short car journeys over a few days, whilst the battery remains uncoded, are unlikely to cause premature aging of the battery.

Battery Fitment

Car batteries are heavy. The process takes 30 mins for a novice: access between the engine and the bonnet is restricted; the car’s battery box is designed to come apart but impossible to re-fit with only a single pair of hands. Duct tape was used to keep the positive terminal from getting in the way during re-fitment.

Once re-fitted, the dashboard lights up. The following problems were forewarned and resolved by a YouTube video:

- Car clock needs resetting

- The steering angle sensor needs resetting by steering full lock to the left, followed by full lock to the right

- The passenger window had been left open during the battery change. The one-click up and down needs resetting by pushing and holding the button at full open (and full close) for 3 seconds.

Following these steps, the dashboard lights were all extinguished.

Battery Coding

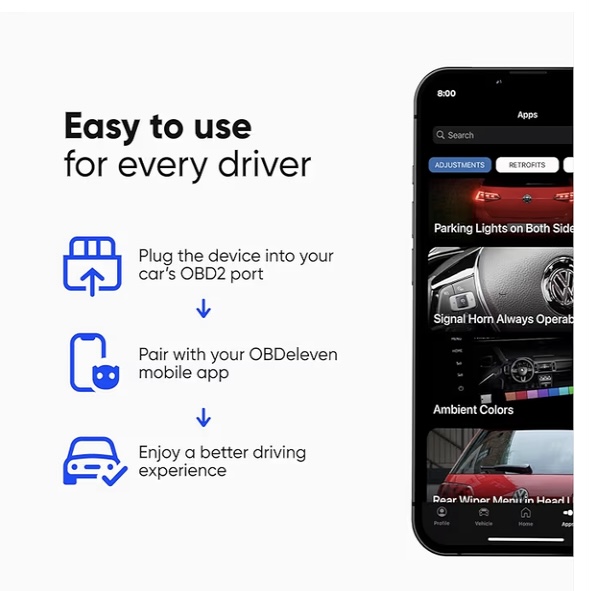

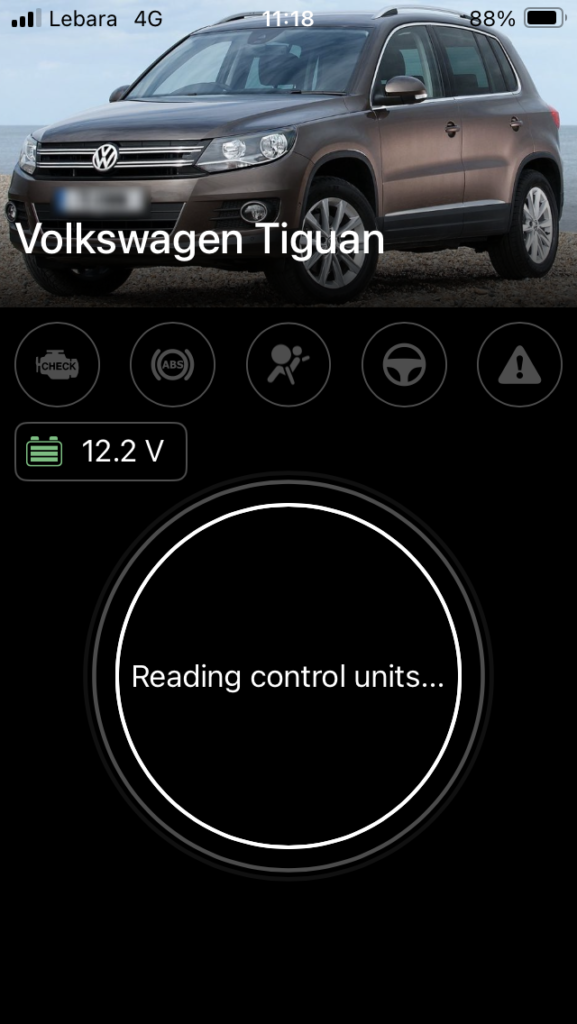

The OBD2 reader arrives later than planned. An online account with OBDeleven is created. Finding the OBD2 port within the car is straight forward and registering the PRO subscription from the iPhone app takes seconds.

Tackling the code registration is fairly daunting given the ‘Long Adaptation’ coding is less than intuitive. There are different methods between vehicle manufacturers and age of vehicles within manufacturer. Sharing information with ChatGPT helped to confirm steps not easily found via website searches alone. A VW specialist would be required if the coding went wrong and the car was incapacitated.

Conclusion

Would I do it again? Yes, though it is disappointing that battery coding cannot be managed directly from a car’s instrument panel. However, now I have an OBD reader, one-year of PRO subscription, plus an old car battery that can be disposed of for £8 at a recycling facility. Total Cost = £210 (130+88-8). The same cost as a fitted, Halfords branded battery.

Anyone need a car battery coding? Only 350 days of the OBDeleven subscription to go. Some of their One-Click Apps look interesting.